What is Pressure Relief Device Risk-Based Inspection (PRD RBI)?

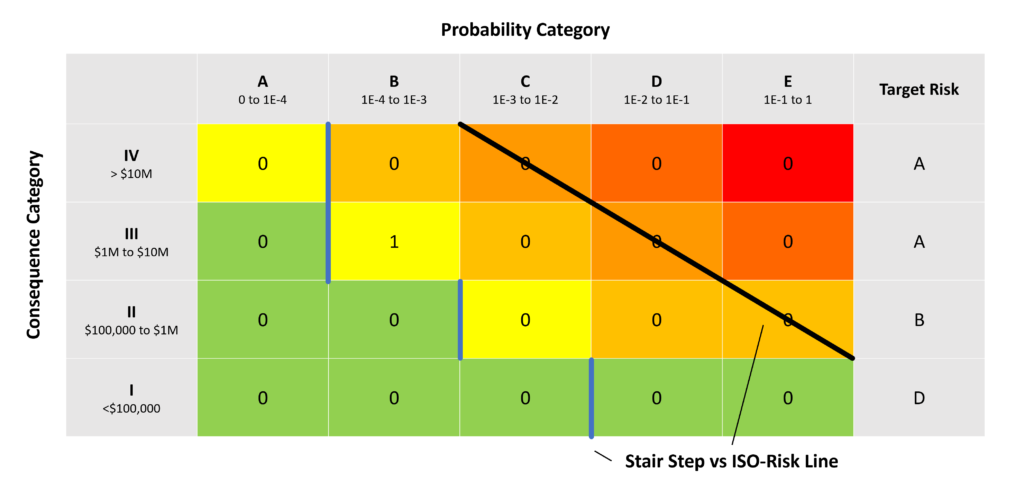

Just as Risk-Based Inspection (RBI) is used on fixed equipment in industrial facilities, it can also be applied to some of the components that help protect them. Properly functioning Pressure Relief Devices (PRDs) are critical for protection of plant equipment and personnel. PRD RBI does not differ in the fundamental concepts of fixed equipment RBI in that you are still assigning a risk based on Probability of Failure (POF) and Consequence of Failure (COF) calculations. Ultimately you are aiming to achieve the same goals of increased safety, improved compliance, and reduction in maintenance and operations costs.

How Can Data-Driven Reliability (DDR) Improve Pressure Relief Device Risk-Based Inspection (PRD RBI)?

Data-driven reliability is the framework for improvement that connects results from your PRD RBI model to your business decisions. This framework leverages reliability intelligence, a unique combination of Subject Matter Expert expertise, and traditional methodology to equip facilities with the information they need to make strategic decisions. Data-driven reliability recognizes that it is not just about collecting as much data as possible, but rather the quality of the data and making sure that it is the right data that fuels these models.

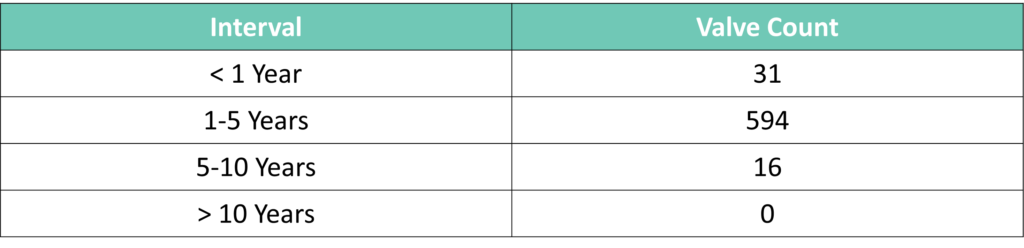

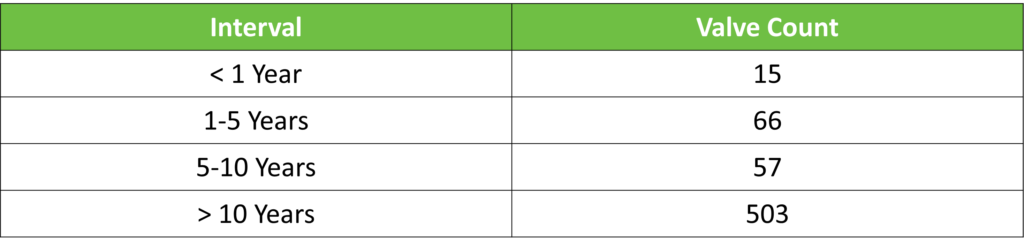

Pinnacle worked with a US refiner who managed their PRD program on a 3 year fixed interval, often driving their TA schedule. 631 PRDs were assessed as part of the scope of the project. The PRD operations and process data such as valve types, P&IDs, test reports, and sizing scenarios were collected and organized along with pertinent consequence data. The below pre and post-analysis results demonstrate how PRD RBI can adjust inspection intervals to increase safety and reduce unnecessary inspection spend.

Inspection Intervals Before RBI

Inspection Intervals After RBI

What Makes Collaborating with Pinnacle Different?

PRD RBI is not a widely adopted methodology in the industry so when a facility is ready to adopt a new program, they are looking to utilize an industry accepted approach and in this case that means an API RP 581 methodology.

Watch Lynne Kaley, Vice President of Research and Development at Pinnacle, talk about how Pinnacle Subject Matter Experts (SME) took the time to break down the calculations to create the only tool that uses the most up to date API 581calculations. In creating the tool, inconsistencies were found in the old methodology and the changes were balloted and accepted as the new official API RP 581 methodology and will be released as part of the 4th edition.

Stay in the know.

Providing data-driven insights, perspectives, and industrial inspiration from the forefront of the reliability transformation.