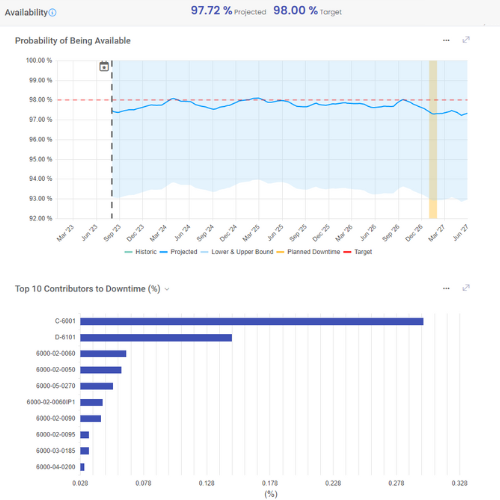

Understand the impact of your decisions on the reliability of your facility in real-time.

Make decisions that drive the right actions.

Today, reliability and operational leaders are making decisions that impact the reliability of their operations. The dynamic nature of economic factors, process changes, and siloed programs make it extremely difficult to connect business goals to reliability activities. Many facilities struggle with static inspection and maintenance plans and do not leverage a dynamic cost/benefit analysis to drive their plans. As a result, these facilities do not understand the quantified reliability implications of operational strategy changes. Data-driven reliability can help you leverage intelligent reliability models that connect your data across your facility’s reliability supply chain, helping you drive long-term reliability performance.

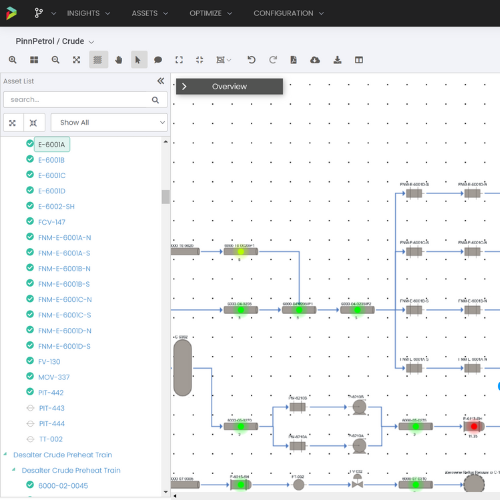

Optimize process and operational strategies

From maintenance and inspection activities to daily operations, every decision that a reliability and operational leader makes has an impact on the reliability of their operations. With data-driven reliability, you’ll be equipped with the information you need to make the best decisions for your facility.

Let Data Drive Your Reliability

Data Collection

Collect and store the right data with quality and efficiency.

Data Organization

Build relationships between your data systems to make your data useful.

Intelligence

Drive reliability with the right data science and engineering models.

Strategic Decisions

Understand the impact of your decisions on the reliability of your facility in real-time.

A Data-Driven Approach to Sustaining and Improving Your MI Program

Whether you are a maintenance manager or a business leader, a data-driven approach to reliability can help you overcome the critical challenges of sustaining your mechanical integrity (MI) program. Identify and prioritize improvement opportunities based on data-driven insights. Better monitor and communicate the effectiveness of program improvements KPIs, metrics, and feedback loops.

Reliability as a Solution is Pinnacle’s fixed price service plus software solution focused on delivering to a quantified result.

Learn about the impacts of Data-Driven Reliability

Article

Case Study: Successful Use of Machine Learning to Model Degradation in Hydrocrackers

Case Study

Reliability Transformation for a Greenfield Facility: Implementing a PSM-Compliant Reliability Program from Startup to Finish