You Have Implemented a Reliability Program, Now What?

So often when implementing or upgrading a reliability program we have seen owner/operators give little thought as to “what happens next.” Learn more about the essentials that make up an effective evergreening program.

What does evergreening mean?

Why is evergreening important?

When first implementing a reliability program, a facility typically has several goals in mind, such as ensuring asset availability, compliance, safety, and reducing unplanned downtime. But what happens when there is no Management of Change (MOC) process in place? All the efforts from a reliability implementation become stagnant without the help of an evergreening process, and a program is only as good as the data that supports it. Depending on the type of program, the specifics of the elements below may change but the core purpose of each component remains critical:

1. Standard Operating Procedures (SOPs)

SOPs should be written prior to the original implementation and should organize program elements to help workers carry out routine operations. Common components found in SOPs are:

Foundational Elements

What is the task? Why is it valuable? For example, an appendix of definitions would be included or conveying the value of a task such as circuitization which has major impacts on other Risk Based Inspection (RBI) elements such as corrosion modeling and inspection plans

Workflows

What are the high-level steps to executing this task?

Communication Plans

Who needs to be informed and when? For example, if a Reliability/Integrity Operating Window is breached, what happens? Who gets notified, and what do they do?

RACI Chart

RACI stands for Responsible, Accountable, Consulted, and Informed and outlines where stakeholder responsibilities fall within the task.

Proceeding and Following Tasks

What tasks need to be completed before this one can start? What tasks follow this task?

2. Working Procedures

Working Procedures can sometimes be combined with the SOPs, but the general purpose is step-by-step instructions on how to physically complete the task (e.g., what buttons to push).

3. Management of Change (MOC) Process

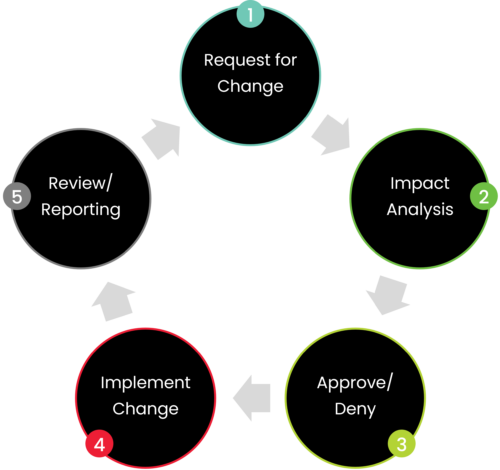

The MOC process is a set of repeatable, documented steps for requesting, logging, assessing, reviewing, and implementing change requests. We recognize that most facilities have a version of this process, but often reliability programs are not appropriately represented. While not all MOCs require reliability steps, our experience has shown us that all MOCs should go through a review by reliability personnel as over 50% require some sort of reliability analysis or change. Although the people or specific step may change, every MOC process should contain the components below:

Request for Change is Made

This may be a result of ongoing project work, team meetings, input from external stakeholders, or other means.

Register and Assess the Change

Change requests are captured in a central log that enables the monitoring of the change throughout the process and includes elements such as related work orders, person/project requesting, deadlines, and potential impacts if the change is not made.

Review and Approve/Deny Requested Change

The change will be reviewed by assigned approval stakeholders, and if deemed valid and necessary, it is then processed through to the execution teams.

Implement Change

This point in the process may include multiple smaller steps and different departments and/or contractors throughout the facility. It is crucial that all work performed is diligently logged in the central MOC log to prevent silos in valuable information. As the change is executed, it is also valuable to log any new risks that arise, trends, or lessons learned from the process.

Review and Reporting

After all changes are made, a final review should be completed to verify the quality of execution by all contributors and to confirm all steps have been logged and archived appropriately for future reference.

4. Training

There are many risks to evergreening and one of the biggest is the human element. To reduce risk associated with turnover, reorganization, and memory, it is important to have well documented training that covers all steps of the evergreening process. SOPs and working procedures are helpful in this process but should not be the only aid used to train new team members.

5. Software

Whether you are implementing a Risk-Based Inspection (RBI), Reliability Centered Maintenance (RCM), or another reliability program, having computer software or other databases to organize data is pivotal. Just as the selection process of your Information Data Management System (IDMS) and Computerized Maintenance Management Systems (CMMS) are important, so is the upkeep and maintenance of these systems since your program is only as strong as the data supporting it.

6. Quality Management Plan

A Quality Management Plan documents the necessary information required to effectively manage project quality includes the project quality standards, Quality Control (QC) procedures, criteria and areas of application, personnel qualifications, authorities, and roles. This document outlines how to set up gate checks for new personnel or tasks as well as who is qualified to perform QC for others.

The Future of Evergreening

Traditionally, projects have relied heavily on the human factor of evergreening, which can be error prone and time consuming. Knowing not only what data to collect, but also how often and when is a critical factor in a successful reliability program. Through implementing the four phases of Data-Driven Reliability (Data Collection, Data Organization, Intelligence, and Strategic Decisions) your program will be set up for evergreening success by putting the right processes in place from the beginning. Learn more about Data-Driven Reliability.

Stay in the know.

Providing data-driven insights, perspectives, and industrial inspiration from the forefront of the reliability transformation.