Learn how we helped a petrochemical facility reduce the number of Loss of Primary Containment (LOPC) failures by implementing a Risk-Based Inspection and Evergreening program.

Challenge

A petrochemical facility was experiencing a high number of LOPC failures from its fixed assets and was looking for a cost-effective way to manage its assets.

Solution

Pinnacle helped the facility to select and implement an IDMS, conduct RBI analysis, evergreen the program, and conduct inspections.

Result

The facility reduced the number of LOPC failures by 62% over seven years and is now set up with plans and procedures for long-term success.

Introduction

A large producer of polyurethane chemicals in North America creates materials for various industries, including the automotive, construction, and aerospace sectors. The facility has specific production objectives focused on efficiently delivering high-quality products to its customers while maintaining availability. To meet these objectives, the facility identified a need to implement a robust Mechanical Integrity (MI) program that would provide a long-term, cost-effective way to manage its assets.

The Challenge

While the facility regularly tracked important asset information such as overall equipment effectiveness, failures, and inspection spend for critical and non-critical equipment, the facility recognized there were improvements that needed to be made in their existing reliability program. For example, asset data was stored in different databases and managed by different teams, making it difficult to develop standardized approaches across the facility. As a result, the facility had a more reactive approach to maintenance and faced multiple challenges, including:

- Inconsistent and siloed data and processes across all groups

- Lack of focused asset strategies

- Difficulty building and implementing evergreening processes

To address these challenges, improve reliability, and create consistency across the site, a site-wide initiative was instituted. The initiative aimed to equip the facility with the tools and resources needed to reduce inspection spend, ensure compliance, and guarantee the safety of its employees and surrounding communities. With this end goal in mind, facility leaders sought a third party to help implement a holistic reliability solution.

Pinnacle's Solution

Pinnacle was brought in as a strategic to develop and implement a proactive Risk-Based Inspection (RBI) and inspection program for the site’s fixed equipment. Pinnacle created a multi-year, four-phase implementation plan which included Inspection Data Management Software (IDMS) selection and implementation, RBI analysis, evergreening, and RBI revalidations. The goal of these strategies was to help the facility efficiently manage its operating risks.

Phase 1

Phase 2

Phase 3

Phase 4

Additional elements of Pinnacle’s solution included field drafting, an embedded inspection team to support planned and unplanned inspections, and several special emphasis projects.

Results

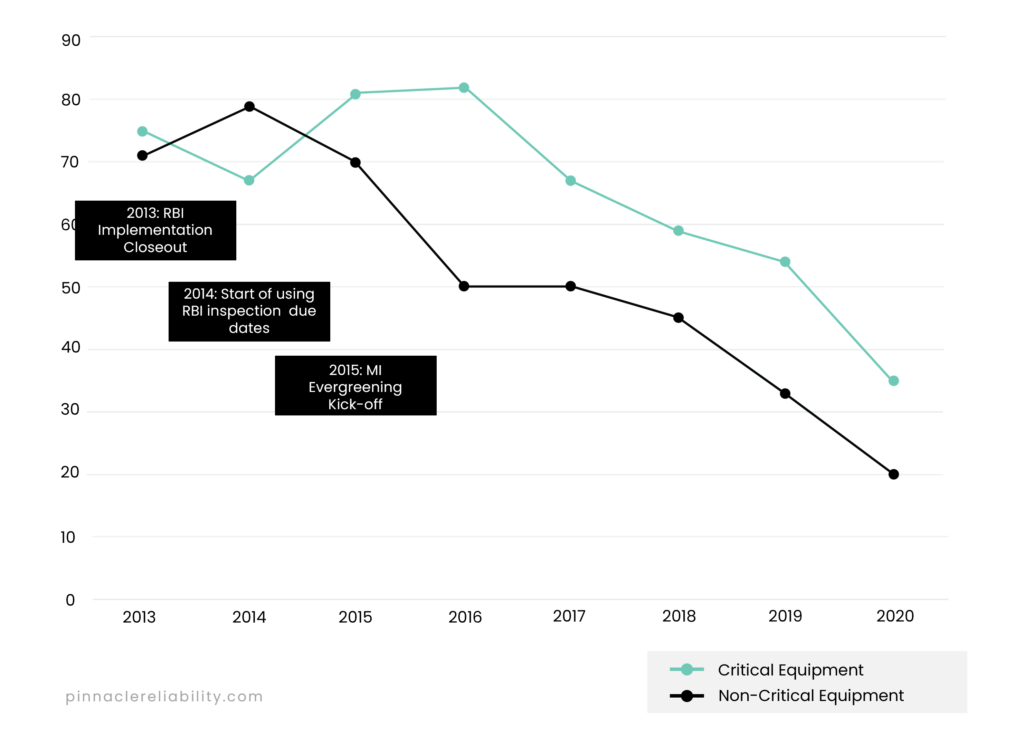

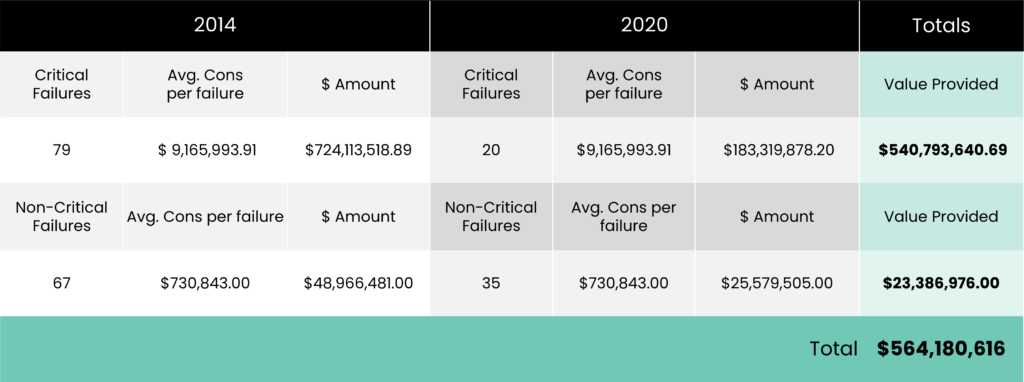

The site split its assets into two groups, one for what it deemed critical and one for non-critical equipment. These categories were determined by the Environmental, Health, and Safety (EHS) impact that asset or circuit had if it failed. Over the years of implementation, the benefits started to become apparent. Using failure reports to track the impact, between 2013 and 2020, the site saw a 72% reduction in critical failures and a 48% reduction in non-critical failures, with an overall site failure reduction of 62%. When multiplied by the average cost per type of failure (critical vs non-critical), there is upwards of $500MM in value over that seven-year span that could be attributed to the improvements in the facility’s MI program.

With the help of Pinnacle, the site received a set of prioritized, tailored risk mitigation strategies that will equip facility leadership with the data they need to make strategic, cost-effective decisions. Leadership buy-in from the site and corporate was instrumental in the success of the implementation and sustainability of this program.

The program was kicked off almost ten years ago. In that time, facility leadership has made better strategic decisions, reduced inspection spend, and significantly reduced the number of LOPC events. Overall, the new program in place also allows for:

- Improved safety and asset integrity

- Optimized inspection plans and spend

- Compliance with best practices and industry regulations

- A robust evergreening plan and procedures

- Improved understanding across the site’s departments on the impact of the work being completed and increased confidence of facility leadership in their data and programs

Conclusion

The success of this facility’s MI program has led to it being the focal point of corporate improvement strategies. In addition to starting the RBI revalidation process for this facility, Phase 4 of this project included the kickoff of a corporate initiative to improve the overall reliability of all the company’s Polyurethane sites. Each facility has now built its own program based on the framework of this US facility.

The next steps for the facility will be to complete the revalidations and continue to evergreen its MI program. As the site collects new data and makes operational and design changes, it is imperative that those changes are implemented into the analysis in a timely manner. Pinnacle is also currently helping implement a non-fixed asset program as outlined in this case study.

To learn more about how Pinnacle can help your facility build its best version of reliability, set up a discovery call.

Stay in the know.

Providing data-driven insights, perspectives, and industrial inspiration from the forefront of the reliability transformation.