Modern production systems are not simple chains of assets operating in isolation. They function as tightly interconnected networks where equipment, processes, and operating conditions influence one another in real time. As this complexity increases, outdated reliability engineering methods fall short. Managing reliability today is less about fixing individual assets and more about understanding how failures propagate across the entire system.

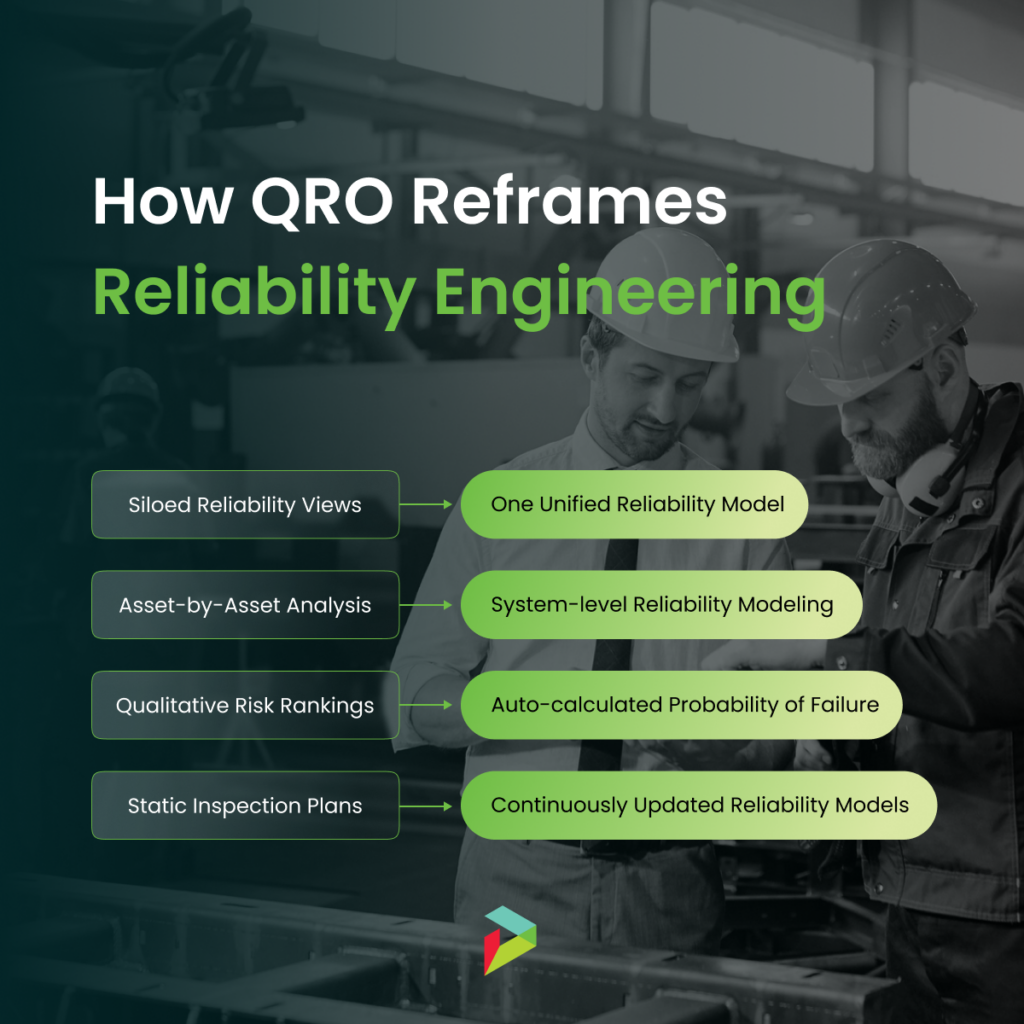

This shift is pushing reliability engineering toward a system-level discipline. With Quantitative Reliability Optimization (QRO), reliability engineering is reframed around quantified system behavior. The focus moves beyond isolated failure events to understanding how failures interact with the broader operation, what impact they truly have, and whether reliability efforts are aligned with the risks that matter most.

Why Complexity Changes the Reliability Problem

Complex production systems have assets that share dependencies, production paths that overlap, and operating conditions that are shifting continuously. A failure does not always appear as a clear shutdown. More often, it shows up as reduced throughput, constrained capacity, or increased maintenance effort long before a defined fault is identified. Multiple minor issues, each seemingly manageable on its own, can combine into significant availability losses.

Traditional reliability engineering typically evaluates equipment on an asset-by-asset basis. Each asset is assessed, ranked, and maintained using isolated risk assessments. In complex systems, this approach creates blind spots. Interdependencies mean the impact of a failure depends less on the asset itself and more on where it occurs within the system and how other components respond.

From a reliability perspective, complexity is driven by interaction, not asset count. When these interactions are not modeled, risk becomes harder to see, prioritize, and manage.

Why Conventional Reliability Engineering Plateaus

Many reliability programs eventually reach a point at which additional effort yields diminishing returns. Programs mature, inspection coverage increases, and analytical rigor improves, yet availability gains begin to slow.

This plateau is not driven by a lack of expertise. It stems from the limitations of the tools and frameworks being used. Static risk rankings struggle in environments where conditions change frequently. Qualitative scoring systems compress broad

ranges of uncertainty into narrow categories, failing to reflect real-world variability. At the same time, data remains siloed across inspection, maintenance, and operations, making it difficult to form a unified view of risk. Human judgment fills the gaps, introducing inconsistency and bias.

As systems grow more complex, these limitations become more pronounced. Reliability engineering becomes increasingly reactive, debates intensify, and availability gains stall- no longer delivering meaningful improvement.

Reframing Reliability Engineering with QRO

Quantitative Reliability Optimization (QRO) addresses these challenges by shifting reliability engineering from asset-focused judgment to system-level quantification. Instead of relying on static models or subjective scoring, QRO integrates facility data into a unified reliability model that reflects how assets degrade, interact, and influence production over time.

QRO auto-calculates the Probability of Failure (PoF) for each failure mode and links those probabilities directly to quantified consequences. This allows engineers to see not just what might fail, but what truly drives system performance, safety exposure, and cost.

As new inspection, process, or condition data becomes available, the model updates automatically, refining uncertainty and adjusting priorities. Reliability planning becomes adaptive, enabling engineers to test scenarios and understand system-wide impacts before work is executed.

QRO strengthens engineering judgment by providing a consistent, data-backed foundation that scales across complex operations. When reliability engineering aligns with system behavior, priorities are clarified. Low-value work can be deferred with confidence because its limited impact is visible and quantified, while high-impact risks surface earlier, allowing targeted action before they escalate into outages. As a result, teams experience:

- Fewer debates driven by subjective risk perception

- Faster, more defensible reliability decisions

- Improved alignment between maintenance, inspection, and capital planning

- Reduced friction across disciplines

- Reliability efforts that directly support availability and business outcomes

Reliability Engineering That Matches System Reality

Complex production systems require reliability engineering that matches their complexity.

By integrating data, auto-calculating the Probability of Failure (PoF), and modeling system-level consequences, QRO enables reliability engineers to move beyond asset-centric thinking. Complexity becomes manageable when risk is quantified, uncertainty is visible, and decisions are grounded in how the system actually behaves.

Learn more about how Quantitative Reliability Optimization (QRO) advances reliability engineering through system-level risk modeling. Connect with the Pinnacle team to explore how this approach can support your facility’s reliability goals.