Reliability engineering has never been short on data. Inspection histories, condition monitoring results, maintenance records, and process data are readily available in most facilities. Yet despite this volume, many organizations still struggle to make confident reliability decisions. Availability plateaus, workloads grow, and debates over inspection scope or maintenance timing become routine.

The challenge is not the availability of data, but the limitations of the tools used to interpret it. Most reliability tools were only built to report conditions, not to continuously translate changing data into system-level decisions. Risk is evaluated periodically, and the Probability of Failure is estimated using fixed assumptions. Most modern analytics tend to visualize trends or flag anomalies, but they leave engineers to interpret what those signals mean in practice.

Without quantified context, more data often leads to more conservative work, not better outcomes. Newton™ software was built specifically to close that gap.

What Newton Software Does Differently

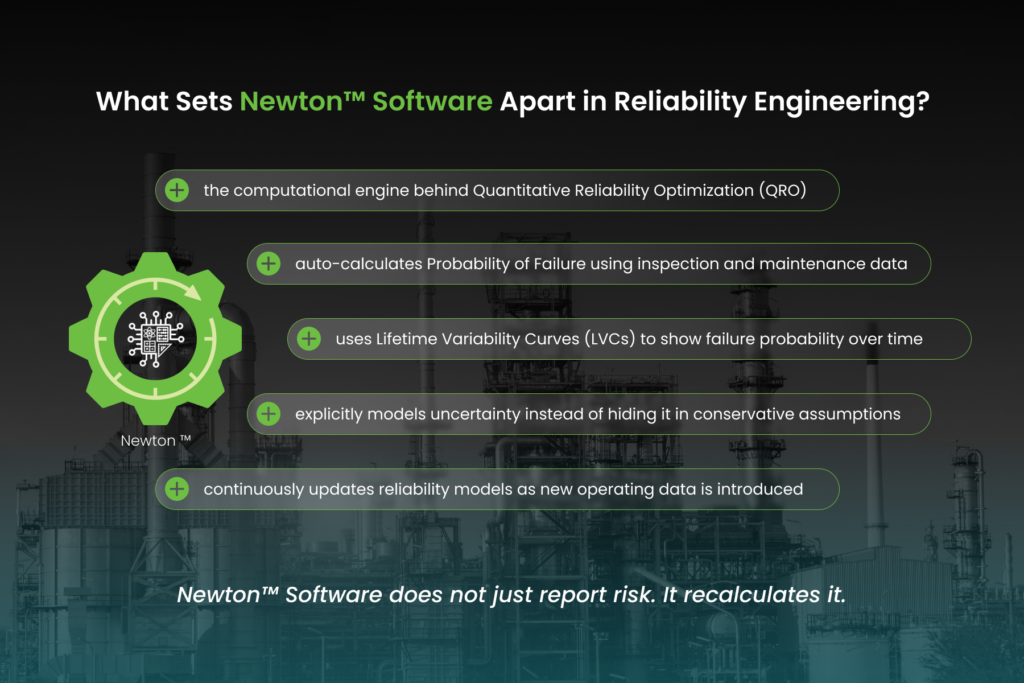

Newton™ is the software engine behind Quantitative Reliability Optimization (QRO). Its role is straightforward but powerful: to continuously calculate reliability risk using real inspection, process, and maintenance data, and to update those calculations as conditions change.

At the core of Newton is the automated calculation of Probability of Failure (PoF) at the failure-mode level. Rather than relying on static inputs, PoF is recalculated as new data enters the model. Inspection results, operational changes, and maintenance actions all affect the output.

Newton™ also uses Lifetime Variability Curves (LVCs) to represent how failure probability evolves over time. Instead of a single expected failure date, engineers see a range of credible outcomes, including earliest and latest failure windows.

Uncertainty is not hidden within conservative assumptions but is explicitly modeled and reduced as better data becomes available.

This results in a living reliability model that reflects how assets are actually behaving, not how they were assumed to behave months or years ago.

Moving Beyond Asset-Level Risk

One of the most common pitfalls in reliability engineering is treating assets in isolation. A high Probability of Failure (PoF) does not automatically translate into high operational impact. Some assets fail frequently with little consequence. Others fail rarely but drive major production losses when they do.

Newton™ addresses this by aggregating asset-level risk models into a system-level view. Assets and failure modes are linked to production, safety, and cost consequences, allowing engineers to see which risks truly matter to availability.

This system modeling capability changes prioritization. It becomes possible to distinguish between work that looks urgent and work that actually improves performance. Engineers can focus on the assets and failure modes that limit throughput, rather than spreading effort evenly across the asset base.

How Engineers Use Newton in Practice

The value of Newton ™ lies in how it supports day-to-day reliability decisions. In inspection and maintenance planning, tasks are evaluated based on quantified risk reduction rather than tradition or perceived criticality. Low-value work can be deferred with confidence, while high-impact actions receive appropriate attention.

During turnarounds, Newton™ allows teams to compare scope scenarios before decisions are finalized. Different combinations of inspections, repairs, and replacements can be evaluated side by side to assess their impact on risk, downtime, and availability. Scope discussions shift from opinion-driven debates to engineering-based tradeoffs.

For capital planning and mitigation strategies, Newton provides traceable justification. Investments can be tested against their impact on system risk and availability, strengthening the business case for action and improving alignment across engineering, operations, and leadership.

Reliability Decisions Backed by Calculation

Reliability improves when decisions are based on quantified risk rather than static assumptions. Newton™ software provides the calculation engine needed to continuously support reliability engineering decisions. By continuously modeling Probability of Failure, uncertainty, and system impact, it enables teams to move from reactive planning to proactive, defensible decision-making.

For organizations looking to improve availability without increasing workload, Newton offers a clearer path forward: fewer assumptions, better prioritization, and reliability decisions grounded in measurable outcomes.

Learn how Newton™, through Quantitative Reliability Optimization (QRO), can support your reliability decisions. Connect with Pinnacle to discuss your environment and priorities.