Machine learning platforms are reshaping reliability work by changing how data is evaluated. Instead of reviewing inspection results, maintenance history, and process data in isolation, these platforms continuously assess them together and update outputs as new information becomes available. Reliability models are no longer locked into fixed cycles. They adjust as operating conditions shift and as data quality improves over time.

This shift moves teams away from static assumptions. Rather than relying on fixed inspection intervals or conservative estimates, machine learning platforms can auto-calculate the Probability of Failure (PoF) for assets and perceived failure modes using real operating and condition data. Risk is evaluated continuously, giving engineers clearer visibility into how degradation and uncertainty evolve.

That said, machine learning on its own does not solve reliability problems. Many analytics platforms stop at prediction or visualization. Dashboards display trends, alerts flag anomalies, and models forecast potential outcomes—but engineers are still left to decide whether the issue matters, how urgent it is, and which action delivers value.

Reliability decisions require context. A calculated failure probability only matters if it is tied to safety exposure, production impact, or cost. When the Probability of Failure (PoF) is not connected to consequence and system-level impact, analytics often reinforce the same outcomes as before: conservative planning, excess work, or decisions driven by experience rather than evidence. This limitation explains why many organizations collect more data yet see little improvement in reliability results.

QRO: Turning Machine Learning into Reliability Decisions

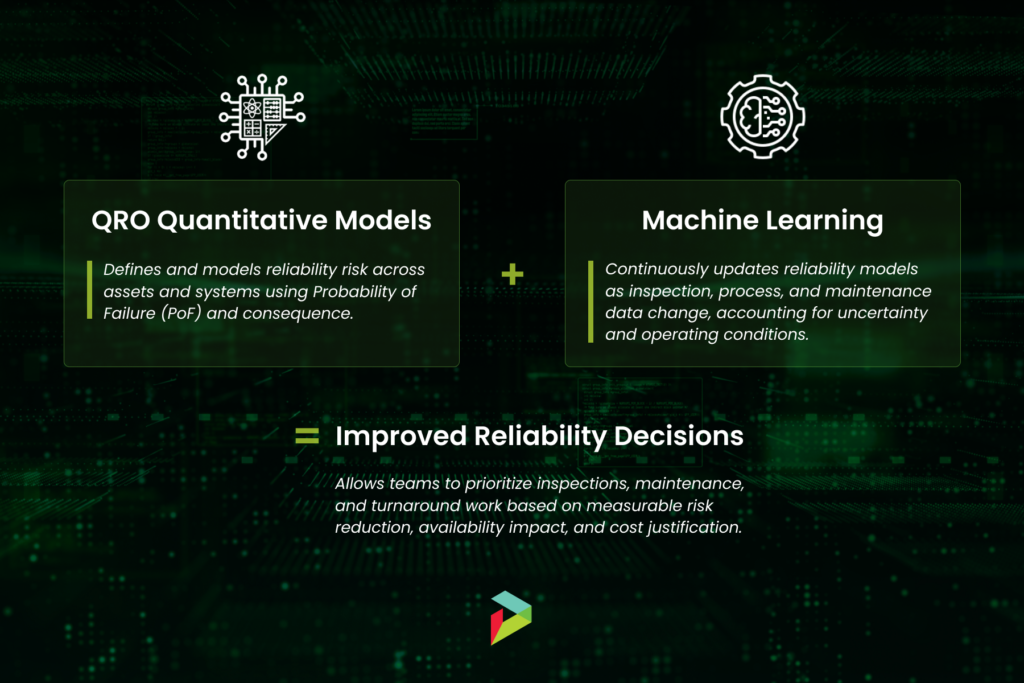

Quantitative Reliability Optimization (QRO) applies machine learning within a defined reliability framework. Instead of using analytics as a standalone tool, QRO integrates machine learning into how reliability decisions are made.

QRO models assets by function and failure mode and connects inspection data, process conditions, and maintenance history into a single quantitative system model. Machine learning supports continuous recalculation of the Probability of Failure (PoF) while accounting for uncertainty in data quality and operating conditions. These probabilities are then combined with consequence modeling, linking technical risk directly to business impact such as availability, cost, and safety exposure.

This structure ensures that reliability decisions are traceable and defensible. Each inspection, maintenance task, or deferral is grounded in quantified risk reduction and system impact. Machine learning increases speed and scale, but engineering logic determines how results are applied.

How QRO Improves Daily Reliability Decisions

In practice, QRO changes how reliability teams plan and prioritize work.

- Inspection planning becomes risk-driven.

Inspection strategies are adjusted based on where uncertainty and failure probability are increasing. Low-value inspections can be safely deferred, while higher-risk areas receive focused, justified attention.

- Maintenance work is prioritized by impact.

Maintenance tasks are prioritized based on their ability to reduce risk and improve system performance.

- Turnaround scope is evaluated before resources are committed.

QRO enables teams to compare alternative turnaround scopes and evaluate their impact on availability, cost, and risk before committing resources.

- Cross-functional alignment improves.

Operations, maintenance, inspection, and engineering work from the same quantitative reliability model. Decisions are based on shared data and models rather than individual judgment, which reduces rework and disagreement.

Reliability with Confidence

QRO ensures that data leads to action by combining machine learning with proven reliability principles and system-level thinking. The outcome is not more analysis, but clearer priorities, faster decisions, and confidence in the work being done.

QRO ensures that data leads to action by combining machine learning with proven reliability principles and system-level thinking. The outcome is not more analysis, but clearer priorities, faster decisions, and confidence in the work being done.

For asset-intensive organizations, this is how reliability moves from a maintenance function to a performance advantage. Explore the QRO approach here.