Inspection programs are central to reliability in oil and gas operations. Every inspection report adds another layer of information about asset health and future risk. Yet many organizations still find themselves overwhelmed by inspection volume while struggling to prevent unplanned failures.

The issue is caused by how inspection data is managed and applied. A modern inspection data management system must do more than store inspection records. It must help teams understand risk, prioritize work, and make confident, defensible decisions. This is where inspection data management is evolving, particularly with the introduction of quantitative approaches such as Quantitative Reliability Optimization (QRO).

The Role of Inspection Data Management in Oil and Gas

Inspection data management systems were initially designed to centralize records. They collect inspection histories, CML readings, corrosion data, findings, and documentation to support API inspection programs, including API 510, 570, 580, and 581. For many facilities, these systems were intended to replace spreadsheets and manual tracking.

Centralized, structured inspection data is essential. However, the real value of inspection data lies in how it informs decisions about inspection timing, scope, and prioritization.

Most inspection data management systems treat inspection data as static inputs reviewed during periodic RBI updates. Between those updates, conditions change, degradation progresses, and new information arrives, yet inspection strategies often remain fixed.

Risk rankings in semi-quantitative RBI outputs are also often too conservative and slow to change, leading teams to over-inspect low-risk assets while relying heavily on experience and judgment to manage emerging risks. Over time, the inspection scope grows, the engineering workload increases, and the connection between inspections and actual risk reduction becomes harder to defend.

What the Best Inspection Data Management System Provides

The best inspection data management system moves inspection data from passive records to active decision inputs. Key capabilities include:

Centralized, high-quality inspection data

- CML-level visibility across assets and units

- Quantitative tracking of degradation trends over time

Fully Quantitative risk context

- Auto-calculated Probability of Failure (PoF) using real inspection and operating data

- Movement beyond categorical or relative risk rankings

System-level perspective

- Insight into how degradation affects unit-level risk and production impact

- Elimination of asset-by-asset decision-making in isolation

Actionable Inputs

- Risk-prioritized inspection and maintenance recommendations

- Defensible justification for deferring non-value-adding inspections

- Clear, traceable linkage between inspection decisions and risk reduction

How QRO Builds on Inspection Data Management

Quantitative Reliability Optimization integrates inspection data into a live reliability model. Rather than evaluating inspection results as static inputs, QRO continuously incorporates new data as it becomes available.

This enables:

- Automatic recalculation of the Probability of Failure (PoF) at the failure-mode and asset level

- Continuous updating of risk profiles as inspection data changes

- Inspection strategies that adapt based on measured risk and uncertainty

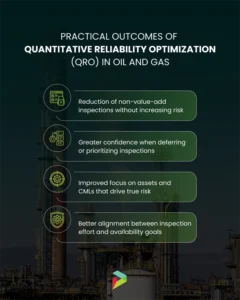

Inspection planning shifts from calendar-driven intervals to risk-informed decisions. Engineers can evaluate the impact of adding, deferring, or modifying inspections using quantified risk rather than assumptions.

Inspection Data Management Has Evolved

The best inspection data management system does more than store inspection data. It enables better decisions.

For oil and gas operators, the evolution toward a fully quantitative approach (QRO) allows inspection programs to become adaptive, defensible, and aligned with real operational risk. When inspection data is treated as a living input rather than a static record, it becomes a driver of reliability rather than an administrative burden.

Learn more about how QRO is applied across inspection and reliability programs. Start a conversation with our team today!