Unlocking Data-Driven Reliability for the Mining Industry

We help you use data to identify problems before they happen.

Use Data to Drive Reliability for Less

The mining industry has a massive impact on the health of the global economy. Reliability is a differentiator for top performers and mining facilities will have strong incentives to optimize their reliability.

Regulatory Compliance

Ensuring compliance with stringent environmental regulations and safety standards is crucial for mining companies. A data-driven approach enables proactive measures to prevent incidents and ensure adherence to regulatory requirements.

Asset Integrity and Reliability

Maintaining the integrity and reliability of extensive mining operations, machinery, and infrastructure is paramount for safety and operational efficiency. Embracing a data-driven approach empowers real-time monitoring and predictive analytics, enabling proactive reliability improvements and downtime reduction.

Siloed Operations

Siloed operations are prevalent in mining organizations, with different teams often focusing on specific mine segments. This division creates barriers to collaboration and limits the integration and utilization of technologies across the entire operation, making it difficult to ensure the mine’s overarching goals are met.

We Help Industrial Leaders Navigate Reliability Digital Transformation

$20MM+

Invested in R&D and Ventures, focused on industrial reliability and data science

2MM+

Assets implemented and analyzed for reliability and integrity programs

500+

Employees dedicated to improving reliability, with 50% embedded in customer sites

20+

Reliability software packages implemented to enable data-driven decisions

Reliability as a Solution

Our fixed price service plus software solution focused on delivering to a quantified result. Back your reliability team with decades of experience.

- Improve reliability uptime by connecting data in single model.

- Dynamically prioritize maintenance and inspection activities.

- Transform culture through standardized processes and training.

$15.5M+

Increased annual revenue

6 Month

Timeline to improvement

Creating a Reliability Culture

Whether you’re in an operations, maintenance, or support function, every role has an impact on your facility. We help create a common, data-driven, framework of reliability that keeps you and your team on the same page.

Our aim is to assist you in prioritizing your time by pinpointing the assets that demand your distinct attention and suggesting the right techniques to employ to address the failure modes of concern.

Our objective is to provide you with a comprehensive overview of your facility’s performance in one glance. This is vital for making informed reliability decisions and mitigating unexpected shutdowns.

Our approach involves creating visible reporting views for all your facilities and collaborating to establish sustainable and scalable reliability work practices. Helping to prioritize resource allocation and minimize unplanned shutdowns, while boosting production.

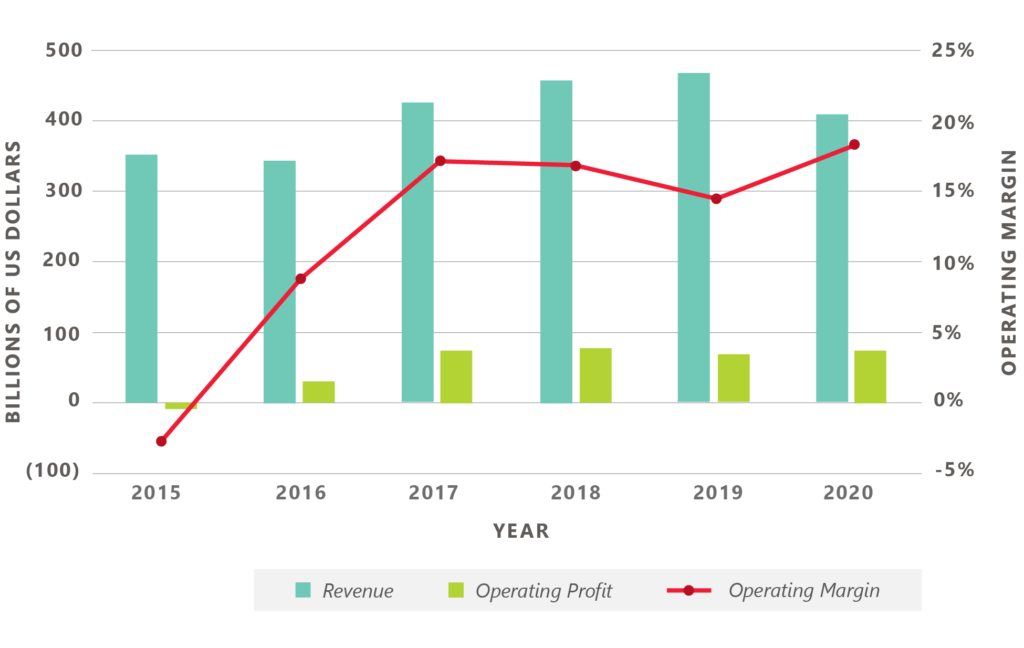

The Economics of Reliability – Global Metal & Fertilizer Mining

As the world economy continues to transform, the health of our global economy depends critically on the success of metal and fertilizer miners. With one third of the world’s economy directly affected by the reliability of operations, reliability can make the difference between being an industry leader and laggard. Throughout this report, we analyze 15 large, publicly traded metal and fertilizer miners, the production levels and corresponding economic value of individual metals and fertilizer components, and identify the key trends that are driving reliability in this crucial industry.

7%

The mining sector spends 7% of the economic value of produced resources on reliability-related activities

Data Talks. Newton™ Listens.

The suite answering “What happens if this compressor blows?” or “Can I push this inspection?”. Single asset strategies are dated. It is time to take a system view of your availability, cumulative costs, and risk exposure for increased facility performance like you’ve never experienced.