Learn how we helped a North American specialty chemical producer improve internal processes and shift site culture by implementing a GE APM Version 4 upgrade.

Challenge

A North American specialty chemicals facility wanted to shift site culture from reactive to proactive by utilizing a GE APM upgrade from Version 3 to Version 4 to be the driver and lay the foundational elements for this change.

Solution

Pinnacle supported the site through work process development, functional design, technical development, implementation, and training.

Result

The organization now has an application that meets its needs, supports its new work processes and provides a foundation for an optimized, data-driven reliability program.

Introduction

A North American specialty chemicals company was experiencing a substantial number of failures at one of its largest facilities. The site’s inspection program was predominantly time-based with minimal optimization efforts. This site incurred multiple unplanned unit and plant downtime events, which drove up operational costs and gained attention at the corporate management level. The attention triggered an effort to move from a reactive culture to proactive and shift from time-based programs to condition-based and, ultimately, risk-based. The customer was a long-time user of the GE APM Inspection Data Management Software (IDMS); however, its version of GE APM was an older, highly customized version that would not provide a platform to drive improvement.

The Challenge

To drive fundamental cultural changes, improve efficiency and effectiveness, and facilitate risk reduction, the site’s Mechanical Integrity Superintendent chose to upgrade the site’s Asset Performance Management (APM) system. As one of the early adopters of GE APM, the site had a long-standing relationship with the software but was not leveraging it to its full capabilities and felt that they were “feeding the software.” The site chose to upgrade its GE APM from Version 3 (V3) to Version 4 (V4). As part of this upgrade, the company wanted to move away from a highly customized version of the system and closer to an “out of the box” solution that would provide a foundation for Mechanical Integrity (MI) improvements with a focus on ensuring sustainability.

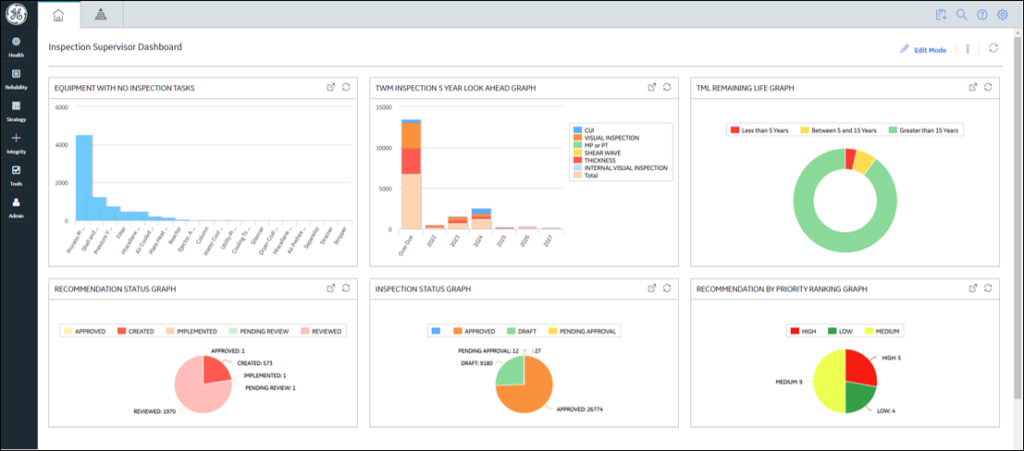

With this implementation, the Mechanical Integrity Superintendent had a goal to create a robust tool to help manage its fixed and non-fixed asset reliability programs. It would also simplify inspection work processes and allow the system to manage the process through the inspection lifecycle, centralize all inspection compliance and documentation into one location, and lay the foundation for a future risk-based inspection (RBI) implementation. The new version of GE APM offered significant upgrades to visualize and monitor the site’s overall program status with role-based dashboards, condition alerts, and compliance management. The new version would allow the utilization of configured checklists to standardize inspection data capture and provide future mobile inspection tools (tablets). The upgraded application also lays the foundation for an eventual RBI implementation.

Pinnacle's Solution

The site was aware of Pinnacle’s reputation and experience with the support of APM program implementations, upgrades, and improvement initiatives and requested a collaboration. This work would consist of Pinnacle helping implement the system and setting the company’s team up for success in the future with workflows and training. Pinnacle partnered with Amplify Technology Solutions (Amplify), a system integrator specializing in technical implementations, integrations, and upgrades of asset management applications. Amplify focused on the technical aspects of the project, while Pinnacle concentrated on the functional elements, including program design, work process design, application testing, training, and support. The upgrade process presented a unique opportunity to design the site’s reliability program of the future first and then design and implement the software to execute that program. The site assessed what was working, identified improvement opportunities, laid the foundation for culture change, and facilitated improvements in its reliability program. Pinnacle and Amplify’s strategic approach to combining the functional and technical aspects of the upgrade has continually demonstrated to be the best approach to delivering successful implementations and, ultimately, ensuring sustainability and return on investment. Pinnacle broke the project into five distinct phases:

- Phase 1: Project Kickoff and Functional Design Consultation

- Phase 2: Technical Design

- Phase 3: Technical Configuration and Data Migration

- Phase 4: Testing

- Phase: 5 Training and Go-live

Phase 1: Project Kickoff and Functional Design Consultation

Pinnacle facilitated a remote workshop with site personnel to review GE APM V4 functionality, identify areas where GE APM “out of the box” functionality could replace V3 customizations, and identify any remaining program requirements. Additional design workshops were conducted to define requirements and workflows for specific functionality, including managing temporary repairs, inspection deferrals, and dashboard design. The result of the functional design phase is the development of a functional design specification that pulls all information together to document requirements, new and updated workflows, and any customizations.

Phase 2: Technical Design

The functional specification from Phase 1 was utilized as the input for the Phase 2 Technical Design phase. This phase focused on the data mapping from V3 to V4 and the technical specifications for any configuration or customizations, including dashboards, reports, and unique functionality requirements. The output of this phase was a technical specification.

Phase 3: Technical Configuration and Data Migration

The technical specification provided input to this phase to build out the application as dictated by the functional requirements. The configuration included building dashboards, configurable checklists, business rules, custom input forms, work processes, and reports. Once the configuration was in place, the data from the previous version, GE APM V3, was migrated to the new environment based on the data mapping defined during the last phase.

At the beginning of the migration, Pinnacle hosted a web conference with the site’s Technical Lead to review the mapping requirements for the migration from V3 to V4 of the GE APM modules and planned for the execution of the data migration. In collaboration with Amplify, data structures were created in the customer’s Quality Assurance (QA) or Test environment. Pinnacle and Amplify then tested the migration results in the GE APM V4 QA environment to ensure that the data was populated as expected.

Phase 4: Testing

Testing was conducted to verify that all “out of the box” functionality, interfaces, and custom configuration was working as defined in the functional specifications. Performance testing was completed to ensure the application was working properly and performing in an acceptable timeframe. Pinnacle built specific test scripts to evaluate all functionality. The scripts were executed by Pinnacle personnel and the representatives from the client, including reliability engineers, inspectors, IT personnel, data clerks, and other maintenance personnel. The testing was utilized to introduce the new version to key personnel to help facilitate the transition.

After the Data Migration and Functional Testing and the organization approved the migration, the site built all remaining configurations in the V4 environment with the support of Amplify to meet the functional requirements as defined in the functional specification.

Phase 5: Training and Go-live

Once the customer testing was completed and approved by the customer, Pinnacle provided custom training based on the requirements, functionality, and work processes. Pinnacle provided role-based training to provide the site personnel with specific knowledge of how to perform the key tasks required for their role. The training took place remotely and was broken into 23 separate two-hour sessions over four weeks, with 105 people completing the training. The training was recorded so that the participants could refer to it as needed or for refresher training. Pinnacle also provided several weeks of support post-go-live to answer questions or resolve any issues. General training was provided to the non-maintenance personnel to familiarize them with accessing information via dashboards and help them understand the site’s use of GE APM.

Pinnacle referenced the experience of prior deployments in previous software versions to plan for the Production environment deployment. Pinnacle performed Production deployment at the agreed-upon date with the site. Pinnacle provided support to the site post-go-live to answer questions, provide follow-up training as needed, provide guidance or input, and resolve issues to ensure that the end-users know and understand how to use the tool post-Production deployment.

Results

The customer engaged Pinnacle early in its evaluation process for initiating the upgrade project. The customer chose Pinnacle because of its significant experience with performing upgrades, expertise in the reliability field, and perspective on how others are using the application. Pinnacle made recommendations and provided perspective on what will work for the customer and where others have run into issues. In addition, Pinnacle was able to support with high levels of expertise to:

- Define the scope for the upgrade

- Manage implementation costs

- Provide external support and expertise

- Remove redundancies in processes

As a result of the GE APM upgrade from V3 to V4, the site now has its APM program for the future with optimized work processes, dashboards to present critical information for decision making, and an emphasis on using data to drive its reliability program. The site now has an APM system closer to “out of the box” that sets them up for more straightforward upgrades in the future. Specifically, the site is better equipped with:

- Documented workflows and recorded training for current and future personnel, creating smoother transitions and consistency and clarity in processes

- Immediate status of their site mechanical integrity compliance through dashboards – what’s coming due, what’s past due, multi-month or multi-year lookaheads, as seen in Figure 1

- The ability to manage their day-to-day work including projected workload, the status of inspections and recommendations, and providing a single, central location of all inspection documentation attached to the inspection.

- The current status of equipment corrosion related to various minimum thicknesses: nominal less corrosion (“safety T-Min”), minimum thickness per company standard, or calculated T-min.

Conclusion

The next step for this site is to start leveraging additional modules within GE APM, such as the Production Loss Analysis module. Now that the customer has the foundational elements of a reliability program in place, they can begin to optimize their asset strategies, such as Risk-Based Inspection (RBI), Reliability Centered Maintenance (RCM), and Failure Modes and Effects Analysis (FMEA). The site can now integrate information from other systems like OSI Plant Information (PI) with APM for more in-depth Asset Health analysis and drive the cultural changes required to migrate from a reactive or fire-fighting mode to a proactive one.

Because of the insights the project produced, the facility aims to better leverage the GE APM RBI module and has embarked on a Maintenance and Reliability Assessment project with Pinnacle to build a roadmap to optimize maintenance spend and better manage risk and improve reliability across the site.

Stay in the know.

Providing data-driven insights, perspectives, and industrial inspiration from the forefront of the reliability transformation.