Data Talks. Newton™ Listens.

The suite answering “What happens if this compressor blows?” or “Can I push this inspection?” Single asset strategies are dated. It is time to take a system view of your availability, cumulative costs, and risk exposure for increased facility performance like you’ve never experienced.

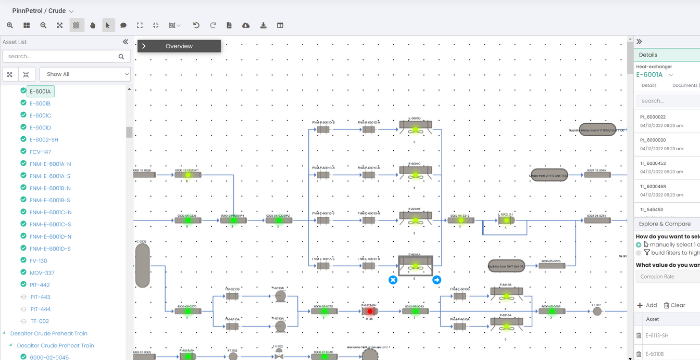

Newton™ allows you to connect

data to business decisions

The Newton™ Suite brings visibility to reliability performance and operations to make your life easier. See daily activities that need to be completed and their link to overall risk and economic impact. The Newton™ Suite delivers the right insights at your fingertips.

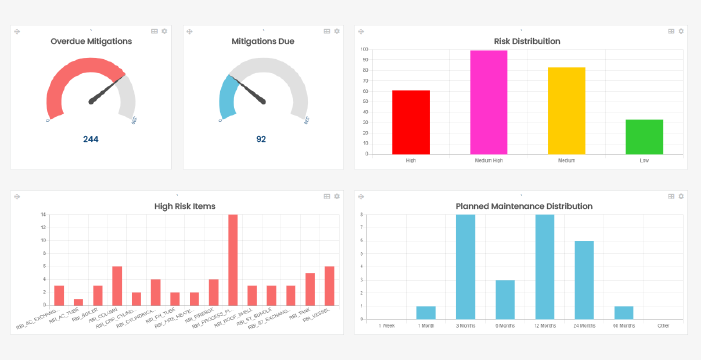

Newton™ Intelligence

Become a reliability superhero. Use our data science models to foresee issues before they happen and get a holistic view of facility availability, cumulative cost and risk so you can meet your goals.

Newton™ RDMS

Manage your inspection and maintenance programs effectively through a modern and configurable user interface while streamlining your processes with connectivity to your CMMS.

Newton™ Integrations

Bring your own data. We make integration with other systems a breeze, whether it is another IDMS, data historian, equipment sensors or even Excel or documents, we got you covered.

Trusted by millions of assets (and their humans)

But don’t just take our word for it. See for yourself what insights are hidden in your data that can take your reliability program to the next level.

What’s Included in the Newton™ Suite?

We check all the boxes of a traditional APM solution, and with Newton™ Intelligence,

we take you to the next level on your reliability journey.

APM

Newton™

RDMS

Newton™

Intelligence

Newton™

Suite

Asset Register/Data

Flexible asset heirachy and data models

Task Tracking and Inspection Data Management

Task management and thickness monitoring

API 580 Based Semi-Quantitative RBI

Traditional approches or Asset Health Monitoring

–

RCM and Maintenance Optimization

Use Reliability-Centered Maintenance (RCM) for improved asset performance

CMMS Integration

Sync asset hierarchy, data, and work order completion

–

Open Data Reporting with Power BI

Leverage PowerBI and our open data for deep insights

Advanced Risk Modeling

Quantitative/Uncertainty based PoF Models and Advanced CoF Models for better Asset Failure Prediction

–

–

Throughput Modeling with Business Intelligence

Live Facility Availability Modeling for performance forecasting and optimization

–

–

Full Stack Facility Optimization

What-if Scenario Management, CML Optimization, Task Optimization, analyze Spare parts and Capital Projects

–

–

Advanced Reliability Operating Windows

Connect operational data to predict asset reliability

–

–

*APM capability according to Verdantix.

See how Newton™ is changing the industrial space

Whether it’s realizing $800,000 in value by optimizing your CMLs, or predicting 94.22% of facility availability, we are evolving the way reliability is done. Read below some of the game-changing benefits our customers are experiencing.

Case Study

Refinery Leverages Advanced Modeling to Optimize CMLs and Recognize $800,000 of Value

Case Study

Supermajor Uses QRO to Predict 94.22% Availability and Associated HSE Risk, Using Model to Drive Benefit-to-Cost Design and Maintenance Optimization

Case Study

CML Optimization Pilot Project Helps Refinery Reduce Risk and Identify Minimum Reduced Inspection Spend of $384K

Reliability as a Solution

Our fixed price service plus software solution focused on delivering to a quantified result. Back your reliability team with decades of experience.

- Improve reliability uptime by connecting data in single model.

- Dynamically prioritize maintenance and inspection activities.

- Transform culture through standardized processes and training.

$15.5M+

Increased annual revenue

6 Month

Timeline to improvement

Join a community of industry leaders

We are partnering with companies of all sizes in the industrial space to help them unleash their true potential. Ready to join?