We make the best technology work for industrial reliability.

From helping you select and implement the best technology to integrating systems across your entire facility, we help you realize value from your technology to drive smarter reliability decisions.

Let’s bring together all your data

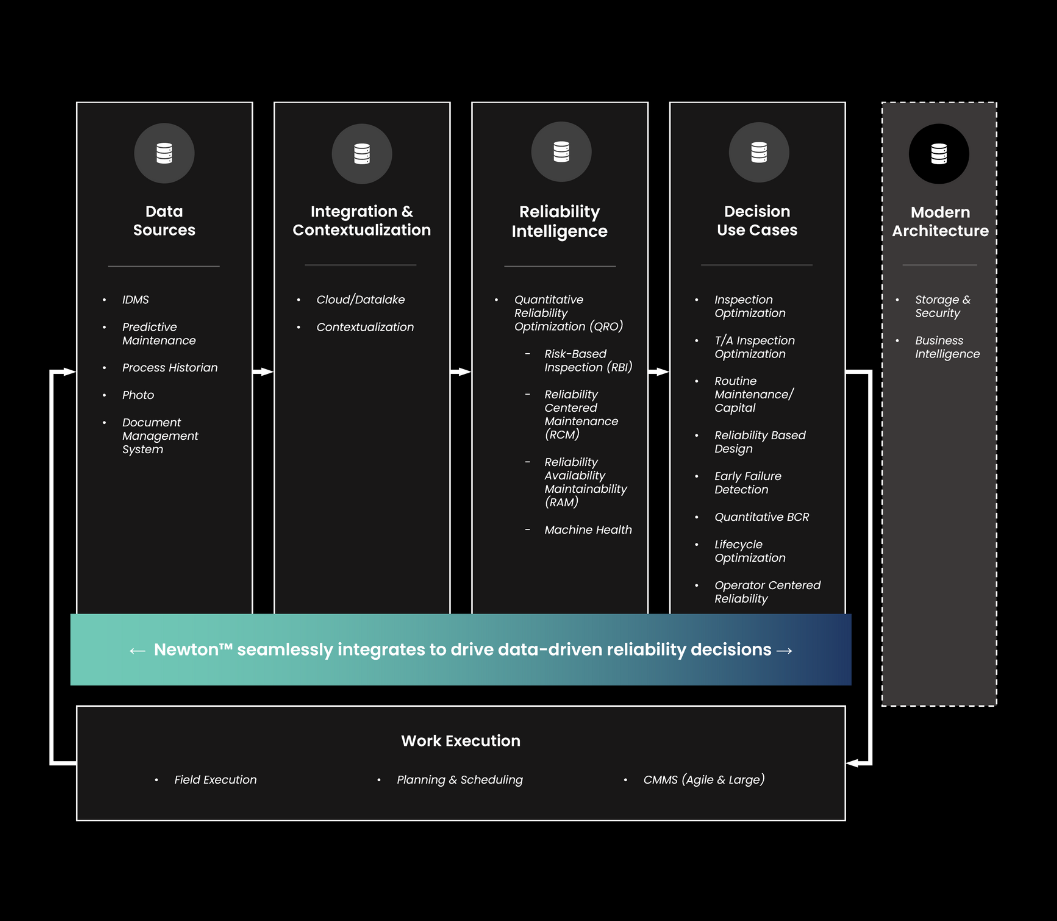

Newton™ is designed to bring together data from various third-party sources that may impact your facility’s reliability. As a single platform, Newton™ helps you combine and automate information to make smarter reliability decisions with more confidence.

Design Documentation and Data

- Build Documentation

- Updated Design Changes

Recent Activities and Plans

- Mechanical Integrity/Reliability Plans

- Preventative Maintenance Tasks

- Process Hazard Analyses

Live Time-Series Data and History

- Mechanical Integrity/Reliability Plans

- Preventative Maintenance Tasks

- Process Hazard Analyses

Our view of the reliability landscape

Pinnacle has implemented and re-implemented countless systems that impact reliability. We answer questions like “what data can I trust?” and “is my data even usable?”. This has been our sole focus for the past 17+ years.

We know reliability isn’t about the software or technology, but rather, it is about the holistic program. We always start from a program perspective to bring in the right data to enable the right reliability decisions to be made.

Our Reliability Partners

We partner with the best of the industry to ensure reliability decisions can be made quickly and efficiently. With experience in over 20 software packages driving selection, implementation, upgrades and migrations, and continuously improving, Pinnacle is uniquely positioned to make sure your technology works for you.

Enabling Technology at Your Facility

Assessment and software selection

We ensure you have the right software and tools to improve your facilities reliability. Whether that is a combination of the data sources you have in place or recommending new.

Configure Software to work for you

With years of experience implementing Newton™ as well as third-party software’s and technologies, we can support your implementation with the end user in mind.

Pilot and test

Import/export capabilities are crucial to making sure data and insights are available fast.

Ensure cultural adoption

We ensure cultural adoption by training your team on how to use the technology. We know it is only as valuable as the use and impression of the people using the tool.

Configure Software to work for you

Sustaining and scaling technology through reliability as a solution. Assess, improve and continuously improve with specific goal to seek.

Reliability as a Solution

Our fixed price service plus software solution focused on delivering to a quantified result. Back your reliability team with decades of experience.

- Improve reliability uptime by connecting data in single model.

- Dynamically prioritize maintenance and inspection activities.

- Transform culture through standardized processes and training.

$15.5M+

Increased annual revenue

6 Month

Timeline to improvement

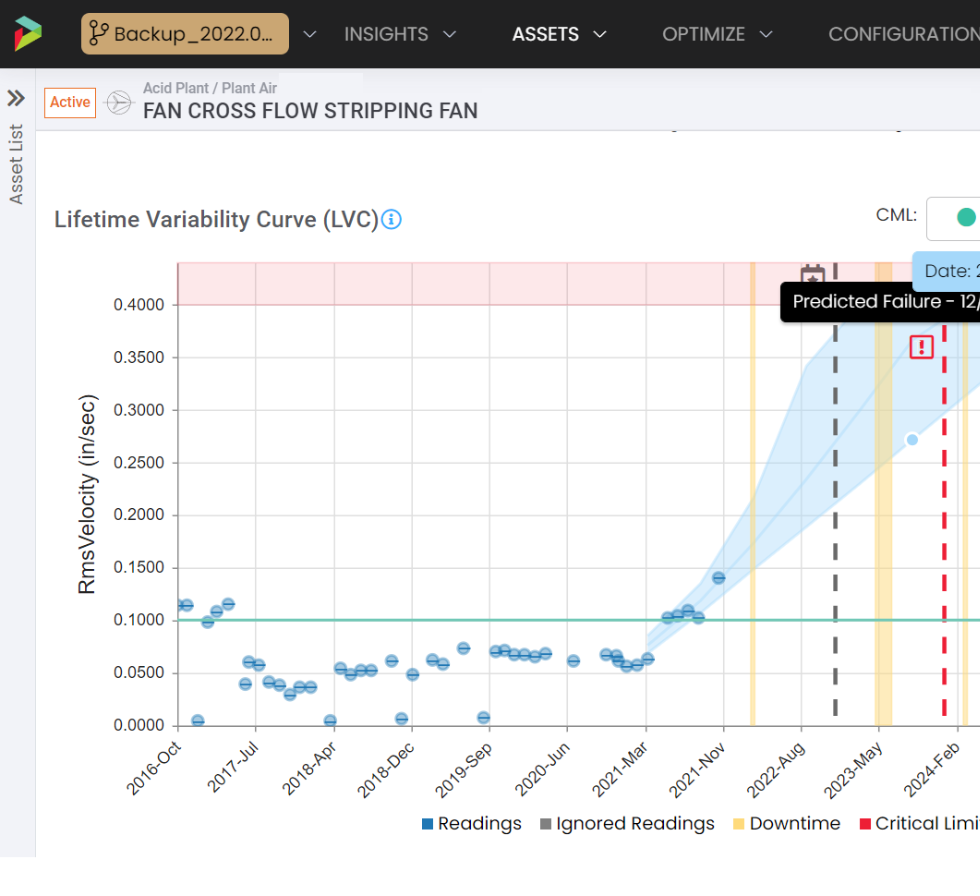

See how Newton™ is changing the industrial space

Whether is realizing $800,000 in value by optimizing your CMLs, or predicting 94.22% of facility availability, we are evolving the way reliability is done. Read below some of the game-changing benefits our customers are experiencing.

Case Study

Refinery Leverages Advanced Modeling to Optimize CMLs and Recognize $800,000 of Value

Case Study

Supermajor Uses QRO to Predict 94.22% Availability and Associated HSE Risk, Using Model to Drive Benefit-to-Cost Design and Maintenance Optimization

Case Study

CML Optimization Pilot Project Helps Refinery Reduce Risk and Identify Minimum Reduced Inspection Spend of $384K

Ready to take your reliability program to the next level?

Newton™ shows you the impact your decisions will have on the performance, availability, risk and cost of your facility. Who wouldn’t want that?