Decision making without the blind spots with Newton™ Intelligence

Overall facility availability, risk, and cost. Only made possible by the suite that is pushing reliability to the next frontier by combining traditional reliability methods with insights from data science.

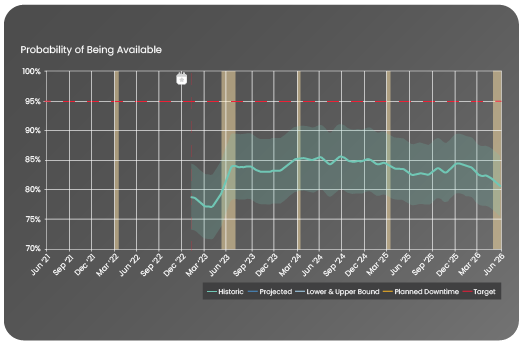

Forecast system performance

with confidence

Live RAM modelling so you can maximize reliability performance by balancing production targets, HSE risks, and the costs of managing both effectively.

- Throughput Modeling with Business Intelligence

- Unit and Asset Availability Forecasting

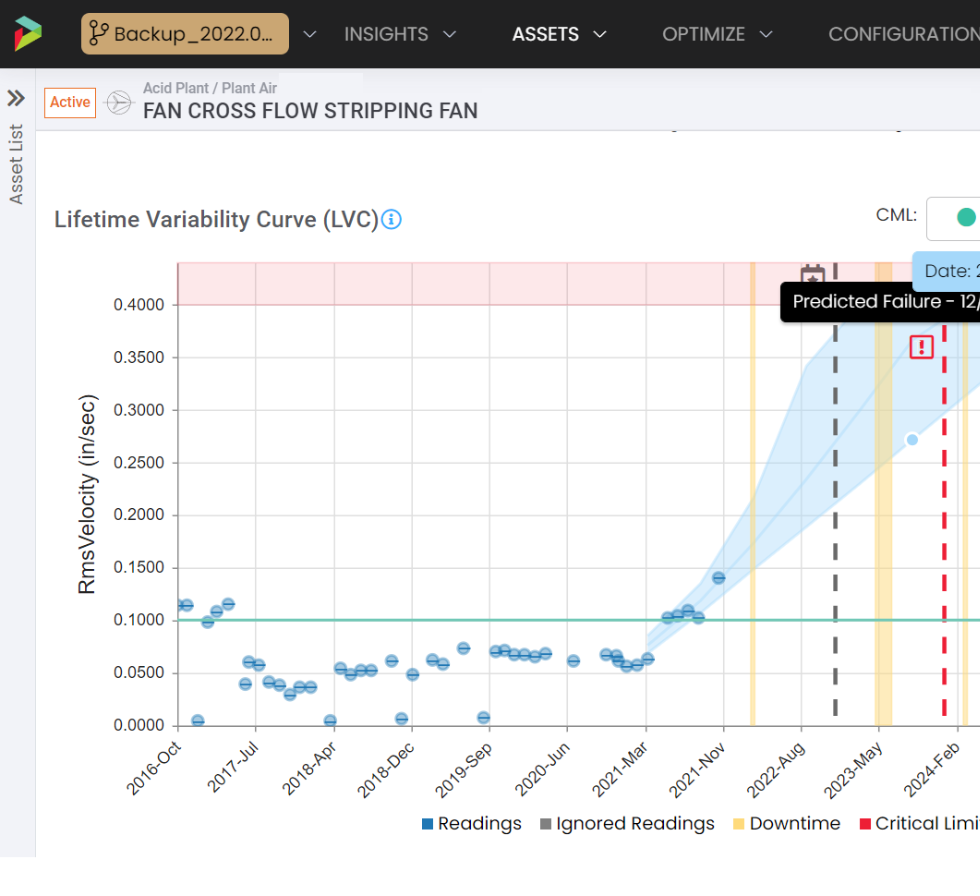

Estimate asset performance and predict failures

Using the concept of a hurricane tracker, the Lifetime Variability Curve (LVC) combines data with subject matter expertise to forecast how the asset will change over time. Think of it as a live Probability of Failure (POF) Curve that improves over time.

- Advanced Risk Modeling

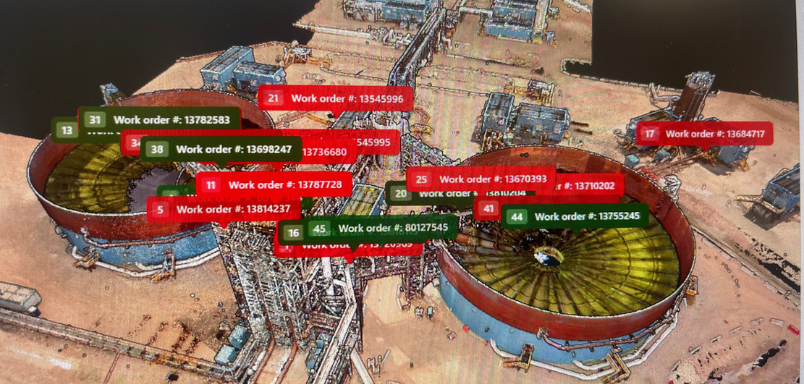

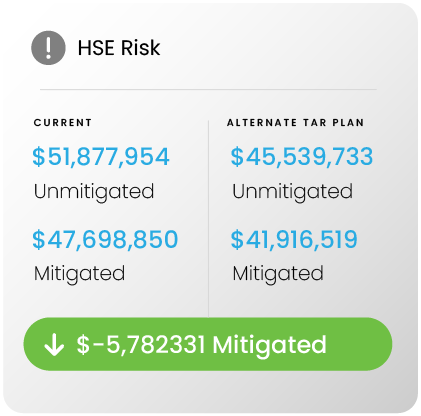

Quantify uncertainty and optimize tasks and spending

Newton™ Intelligence allows you to integrate loss of containment risk with loss of function quantitatively in a single platform so you can effectively compare risks and prioritize resources across different asset classes.

- Full Stack Facility Optimization

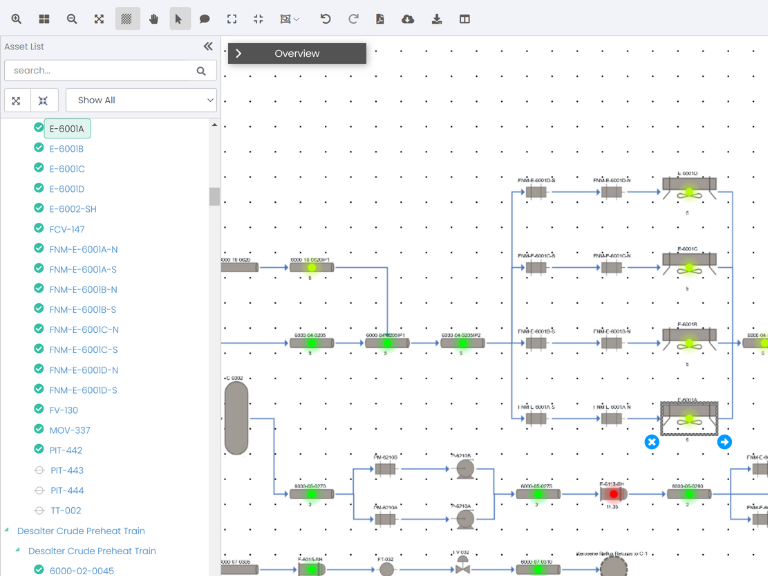

See how each action impacts reliability, performance, and availability at the system level

It’s time you break down the silos around your equipment. Reliability Simulation & Performance Optimization provides the insights to move away from individual tasks for individual assets and truly focus on the high-level reliability of your systems.

- Full Stack Facility Optimization

What’s Included in the Newton™ Suite?

We check all the boxes of a traditional APM solution, and with Newton™ Intelligence,

we take you to the next level on your reliability journey.

APM

Newton™

RDMS

Newton™

Intelligence

Newton™

Suite

Asset Register/Data

Flexible asset heirachy and data models

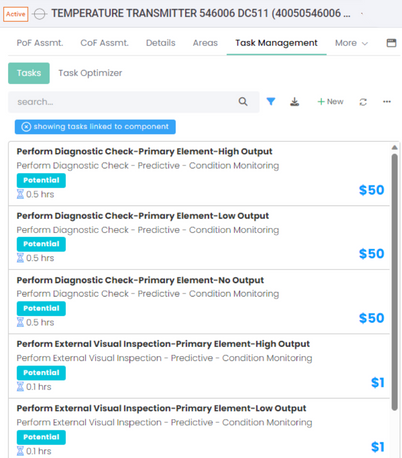

Task Tracking and Inspection Data Management

Task management and thickness monitoring

API 580 Based Semi-Quantitative RBI

Traditional approches or Asset Health Monitoring

–

RCM and Maintenance Optimization

Use Reliability-Centered Maintenance (RCM) for improved asset performance

CMMS Integration

Sync asset hierarchy, data, and work order completion

–

Open Data Reporting with Power BI

Leverage PowerBI and our open data for deep insights

Advanced Risk Modeling

Quantitative/Uncertainty based PoF Models and Advanced CoF Models for better Asset Failure Prediction

–

–

Throughput Modeling with Business Intelligence

Live Facility Availability Modeling for performance forecasting and optimization

–

–

Full Stack Facility Optimization

What-if Scenario Management, CML Optimization, Task Optimization, analyze Spare parts and Capital Projects

–

–

Advanced Reliability Operating Windows

Connect operational data to predict asset reliability

–

–

*APM capability according to Verdantix.

Seamless integrations

Newton™ Integrations allows you to connect all your data sources quickly. Unlock justified reliability decisions on a single screen.

See how Newton™ is changing the industrial space

Whether is realizing $800,000 in value by optimizing your CMLs, or predicting 94.22% of facility availability, we are evolving the way reliability is done. Read below some of the game-changing benefits our customers are experiencing.

Case Study

Refinery Leverages Advanced Modeling to Optimize CMLs and Recognize $800,000 of Value

Case Study

Supermajor Uses QRO to Predict 94.22% Availability and Associated HSE Risk, Using Model to Drive Benefit-to-Cost Design and Maintenance Optimization

Case Study

CML Optimization Pilot Project Helps Refinery Reduce Risk and Identify Minimum Reduced Inspection Spend of $384K

Throughput Modeling with Business Intelligence

Reliability as a Solution

Our fixed price service plus software solution focused on delivering to a quantified result. Back your reliability team with decades of experience.

- Improve reliability uptime by connecting data in single model.

- Dynamically prioritize maintenance and inspection activities.

- Transform culture through standardized processes and training.

$15.5M+

Increased annual revenue

6 Month

Timeline to improvement

Newton Intelligence™ identified more than 11,000 CMLs that added cost without adding value, which is projected to save over $400,000 for the facility over the next five years.

– Mark Felder, Chief Technology Officer

Ready to take your reliability program to the next level?

Newton™ Intelligence shows you the impact your decisions will have on the performance, availability, risk and cost of your facility. Who wouldn’t want that?