Unlocking Data-Driven Reliability for the Midstream Industry

We help you use data to identify problems before they happen.

Use Data to Drive Reliability for Less

The midstream industry has a large impact on the global economy as illustrated by the rapid growth of natural gas and other midstream elements. As demand for these products continues to increase and midstream companies face the

challenge of aging infrastructure, reliability will become even more of a differentiator for top performers.

Infrastructure Maintenance

Aging infrastructure, including pipelines, storage tanks, and terminals, requires ongoing maintenance and occasional expansion to meet increasing demand and evolving safety standards. Implementing a data-driven approach helps midstream companies optimize infrastructure maintenance and minimize downtime.

Environmental and Regulatory Compliance

Ensuring compliance with stringent environmental regulations and safety standards is crucial for midstream companies. A data-driven approach enables proactive measures to prevent environmental incidents and ensure adherence to regulatory requirements.

Asset Integrity and Reliability

Maintaining the integrity and reliability of a vast network of pipelines, storage facilities, and equipment is key for safety and efficiency. A data-driven approach enables real-time monitoring and predictive analytics, proactively enhancing reliability and reducing downtime.

We Help Industrial Leaders Navigate Reliability Digital Transformation

$20MM+

Invested in R&D and Ventures, focused on industrial reliability and data science

2MM+

Assets implemented and analyzed for reliability and integrity programs

500+

Employees dedicated to improving reliability, with 50% embedded in customer sites

20+

Reliability software packages implemented to enable data-driven decisions

Reliability as a Solution

Our fixed price service plus software solution focused on delivering to a quantified result. Back your reliability team with decades of experience.

- Improve reliability uptime by connecting data in single model.

- Dynamically prioritize maintenance and inspection activities.

- Transform culture through standardized processes and training.

$15.5M+

Increased annual revenue

6 Month

Timeline to improvement

Creating a Reliability Culture

Whether you’re in an operations, maintenance, or support function, every role has an impact on your facility. We help create a common, data-driven, framework of reliability that keeps you and your team on the same page.

Our aim is to assist you in prioritizing your time by pinpointing the assets that demand your distinct attention and suggesting the right techniques to employ to address the failure modes of concern.

Our objective is to provide you with a comprehensive overview of your facility’s performance in one glance. This is vital for making informed reliability decisions and mitigating unexpected shutdowns.

Our approach involves creating visible reporting views for all your facilities and collaborating to establish sustainable and scalable reliability work practices. Helping to prioritize resource allocation and minimize unplanned shutdowns, while boosting production.

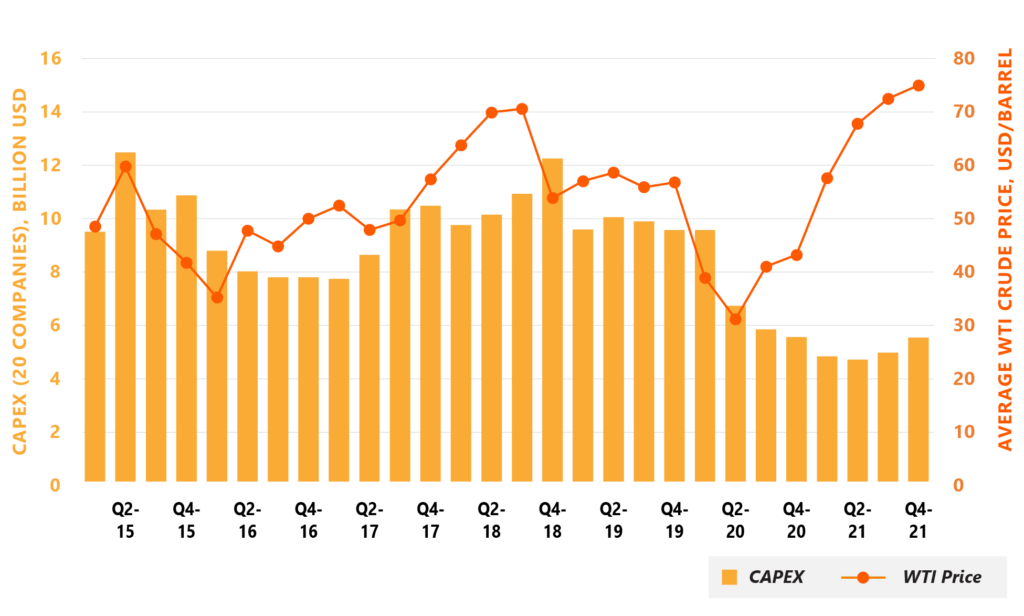

Economics of Reliability Report – US and Canada Midstream Oil & Gas,

In our Economics of Reliability Report – US and Canada Midstream Oil & Gas, we dive into the financial and operational performance data of 20 publicly traded midstream operators. Download a copy of our report to learn more about how reliability impacts the midstream industry and to see how your company compares to industry leaders

$29B

Estimated total reliability spend for the midstream industry in the US and Canada is US$29 billion per year.

Data Talks. Newton™ Listens.

The suite answering “What happens if this compressor blows?” or “Can I push this inspection?”. Single asset strategies are dated. It is time to take a system view of your availability, cumulative costs, and risk exposure for increased facility performance like you’ve never experienced.